How it's Made

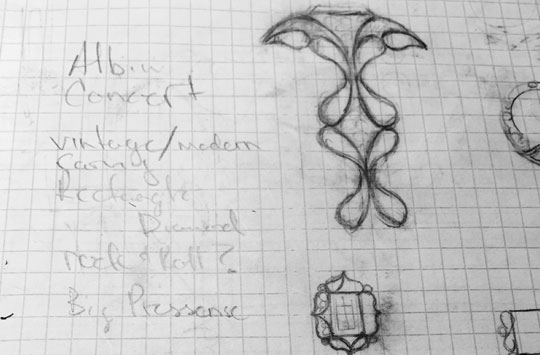

Design Concept:

A Talis Jewel will begin its journey as just a simple thought. That thought eventually becomes an idea, and from that idea a conceptual design will be made. This design will usually be in the form of a rough sketch, and that rough sketch will serve as our template and guideline to follow in our production process.

Conceptual Sketch

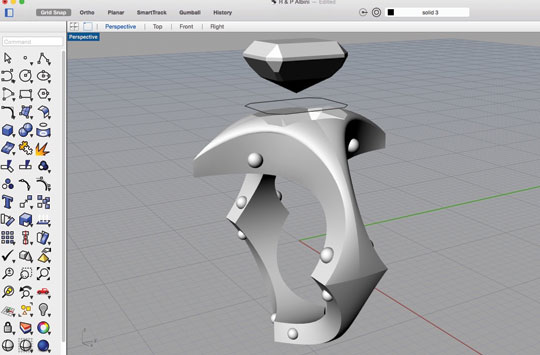

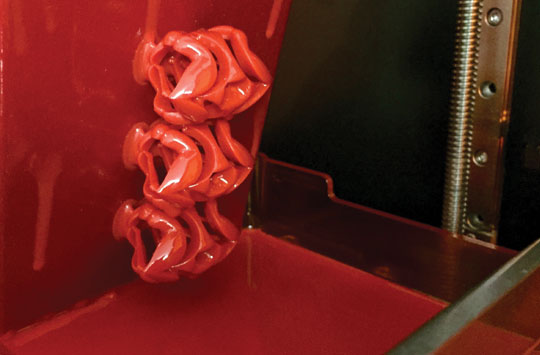

Prototype:

After a design concept has been established we will then proceed with the production of a prototype model. Throughout this production we will use old and new processes such as, Wax Carving, CAD Rendering, 3D printing and Metal Fabrication, to not only fine tune our design, but ensure that the Jewel being made will be structurally sound as well.

Wax Carving

CAD Rendering

3D Printing

Metal Fabrication

Model Overview:

Once the basic model of our prototype has been completed, we will stop and conduct an overview of our work to make sure that our sizes and fitments are correct before proceeding with any final touches.

Model Overview

Stone Layout:

With our basic model now completed we can finalize the design by deciding the best way to layout our accent stones, once the most appealing pattern has been discovered we will then carefully drill that pattern out into our model.

Stone Layout

Sprueing:

The sprueing of our model is the first step we will take towards the making of our mold. These sprues will act as channels for liquid wax, and eventually liquid metal to follow later on in the casting process. The placement of these sprues is crucial and varies from design to design.

Sprueing

Mold Making:

With the sprues now attached to our model we can proceed with the making of a mold. This mold will be made by enclosing the model with either liquid silicone or heated rubber. Once solidified the mold will then be carefully cut apart and our model will be removed. The resulting cavity will then be injected with liquid wax to produce exact replicas of our model. These waxes will then be taken and casted into the desired metal that will eventually become our Jewel.

Mold Injected with Wax

Casting:

Now that our waxes have been casted into our desired metal, those castings will then be carefully inspected for distortions and possible imperfections such as shrinkage, and porosity. If no such imperfections can be found we will then proceed with the final production of our Jewel.

Platinum Castings

Platinum Castings

Cleaning of Casting:

When metal is casted its surface does not come out smooth, or shiny, on the contrary it comes out rough and dull. So for our castings to reach their desired appearance they must be thoroughly cleaned. This involves

carefully using abrasives such as files, emery paper, and rubber wheels to smooth over and remove the rough surfaces of our castings.

Cleaning of Castings

Assembly:

After every square inch of our castings have been cleaned, and we have triple checked our sizings and fitments, we can then assemble our Jewel by permanently attaching our castings together by pinning, laser welding, and or soldering them together.

Soldering

Stone Setting:

A great deal of care and time will go into this process. Precise measurements of the stones will be taken and then those stones will be meticulously set into our Jewel. This is all done with the use of a microscope to ensure that not only every stone is set as close to one another as possible, but that they are all set on the same level and plane as well.

Stone Setting

Polishing:

With our pieces assembled and our stones all set we can then begin putting the desired finish or polish onto our Jewel. There are various techniques and tools that can be used to achieve our finish, and almost all involve the use of multiple abrasive compounds. By using these compounds in order from coarsest to finest we can achieve anywhere from a dull satin finish all the way up to a glimmering high polish.

Polishing

Ultrasonic Cleaning:

Unfortunately polishing jewelry is a messy affair, so a thorough cleaning is required after our final finish has been applied. This is be done by placing our Jewel in an ultrasonic cleaner. The cleaner will then use high frequency sound waves to remove all residue left over from the finishing process.

Ultrasonic Cleaning

Steam Cleaning:

After sitting in the ultrasonic cleaner for a while our Jewel will then be blasted with powerful jets of steam to ensure a clean and flawless finish.

Steam Cleaning

Quality Control:

Before our completed Jewel may leave the shop it must be thoroughly inspected under magnification to ensure that it passes our strict quality control standards.

Quality Control

Finished Jewel:

And finally after many, many hours of hard work and care, our Jewel is proudly ready to go out and become a very special part of someones life.

Finished Jewel